Injection Molding Services for Custom Parts

Custom injection molding for plastic prototypes and on-demand production parts in as fast as 1 day. Request an injection molding quote today.

Certifications ISO 9001:2015 | CTQ Inspections | ITAR

ISO 13485 certification available through promakehub Network

Injection Molding Processes

Make the move from prototyping to on-demand manufacturing for affordable, high-quality molded parts within days. Better yet, your prototyping tool is free once you shift to an on-demand manufacturing tool. Working with a single supplier that provides free design consultation services also massively speeds up the manufacturing process, allowing for greater supply chain flexibility, more consistent parts, and making qualification a breeze.

Plastic Injection Molding

Learn More

Liquid Silicone Rubber Molding

Learn More

Insert Molding

Learn More

Overmolding

Learn More

Additional Capabilities for Injection Molding Orders

Explore popular material choices based on key characteristics like corrosion or UV resistance.

How to Calculate Your CNC Machine’s Power Consumption

What Determines the Hourly Rate for CNC Machining?

What’s the Real Price of a Small CNC Machine?

How Many Axes Does a CNC Machine Have?

Unlocking the Axes of CNC Machines: A Complete Guide

How Loud Are CNC Machines? The Truth About Workshop Noise

Injection Mold Tooling Options and Quality Reporting

We have two unique offers to meet your needs wherever you are in the product lifecycle. Our process helps you cut product development cycles by weeks—sometimes months—and bridge to production with injection-molded parts within days. Our process is designed to meet your production needs, and helps you qualify parts quickly to seamlessly transition into production with scientific molding, in-process CMM inspections with GD&T, and a full suite of secondary operations to make sure that your parts show up and perform as expected.

| Prototyping | On-Demand Manufacturing | |

|---|---|---|

| Objective |

I need to validate my design at Promakehub speeds. I need the flexibility to economically iterate before production. |

I have on-demand Promakehub needs at Protolabs speeds. |

| Best When |

|

|

| Mold Cavities | Single | Single and multi-cavity |

| Mold Life | Limited (guaranteed for at least 2,000 shots) | Unlimited |

| Mold Storage | Stored for 18 months of inactivity | Stored for 3 years of inactivity |

| Mold Ownership | Upon request | Yes |

| Quality Documentation | Quality Inspection Report (QIR) verifies Promakehub’ manufacturing process controls |

|

| Shared Features |

Aluminum molds |

|

Why Choose Us for Custom Injection Molding?

Unmatched Lead Times

Reduce your product development cycle by weeks—sometimes months—and bridge to production with injection-molded parts within days. Some injection molding orders can ship in as fast as 1 day.

Design for Manufacturing Feedback

Every quote includes real-time pricing and design analysis. We evaluate your 3D CAD and help identify any features that may pose challenges during the molding process such as difficult to machine undercuts and insufficient draft.

No Minimum Order Quantities (MOQs)

Procuring parts on demand, without MOQs, helps you manage market or demand volatility and provides a cost-effective source for bridge production, line-down emergencies, end-of-life production, or product customization.

Injection Molding Expertise

We’ll work with you throughout the course of your project to help you quickly move from prototyping to production, including finishing options and inspection reporting

Supporting Subheading

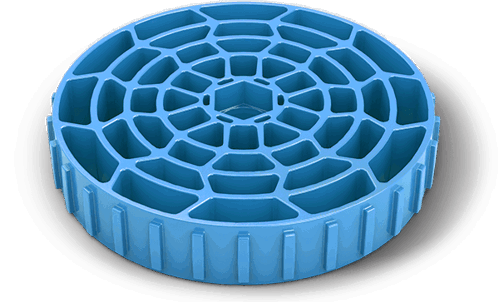

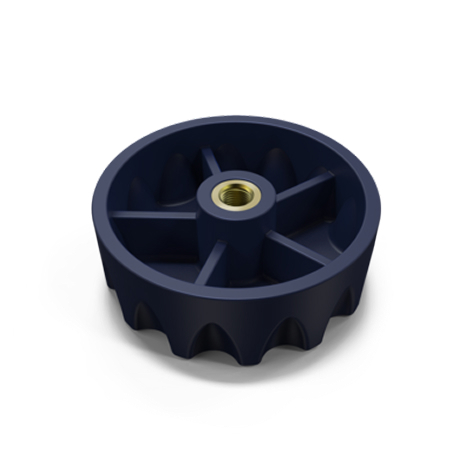

Advantages of Injection Molding

Injection molding is plastic manufacturing process that can produce high quality parts at scale. It’s typically used for low- to high-volume production but our aluminum tooling can also make prototyping runs economical.

- Low cost at higher volumes

- Exceptional part cosmetics and surface finish

- Repeatable

- Complex parts

- Low scrap rate

- Large selection of thermoplastic and thermoset materials

Injection Molding Applications

Injection molding is widely used for plastic part production in medical, consumer, and automotive industries. Typical parts include:

- Housings

- Brackets

- Gears

- Single-use medical parts

- Electrical connectors

- Syringes

- Containers

Find the Right Material

Explore popular material choices based on key characteristics like corrosion or UV resistance.