Manufacturing Components for the Aerospace Industry

Fictiv accelerates innovation and simplifies sourcing for aerospace – from prototype to production.

Instant pricing & DFM

Design & Manufacturing Guidance from Industry Experts

ISO 9001:2015 quality certification

Tight tolerances & 2D drawings accepted

In-Network Finishing, Joining and Assembly

Aerospace Manufacturing from Prototype to Production for New Product Development

Fictiv only supports manufacturing of aerospace parts for non-export-restricted projects.

Prototyping

Rapid turn-around times for early stage designs with a wide range of 3D printing technologies and urethane casting.

Rapid turn-around times for early stage designs with a wide range of 3D printing technologies and urethane casting.

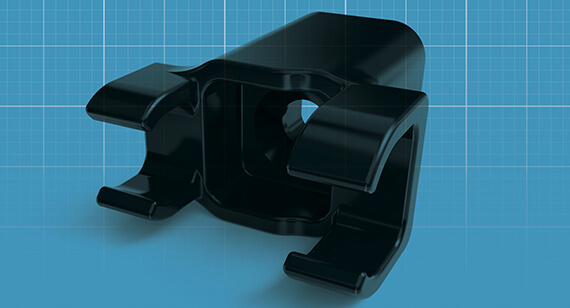

Detailed prototypes for complex geometry

Rapid Urethane Casting

Looks-like models

Rapid Multi Jet Fusion 3D Printing

Engineering Validation Testing

Iterate quickly on high-precision, functional prototypes with tight-tolerance CNC Machining, Gear Hobbing, and Rapid Design Molds.

Precision gear manufacturing

High quality design options for Design of Experiments

Rapid Design Molds with steel tooling at low quantities

Optimize material properties for your design

Wide selection of materials available for CNC Machining

Design Validation Testing

Validate part strength, functionality, and aesthetic finish with production-grade injection molding at prototype speeds and CNC machining with a wide range of finishing options.

High quality parts for testing strength and vibration

Rapid Design Molds with steel tooling at low quantities

Validate appearance and durability of surface finish

A wide range of post-processing options available for CNC Machined parts

Production Validation Testing

Prepare your designs for scale, with production-grade manufacturing capabilities at low volumes and advanced quality control services with transparent documentation

Rapid delivery of production quality parts to verify manufacturing method

Production Tooling at low volumes

Test fixtures to verify functionality and yield of production-ready parts

CNC Machining with fast lead times

Production

Seamlessly transition into production, with end-use parts delivered rapidly and adoption of your precise quality requirements into the Fictiv manufacturing system.

Tight tolerances on precision metal parts at production quantities

Precision CNC Machining with tolerances as tight as +/- 0.0002 in

Custom plastic parts for production in quantities from 10 – 1M units

Injection Molding with a wide range of secondary operations

Custom quality inspection plans and volume discounts

Available with Fictiv Enterprise

Fictiv’s digital manufacturing platform has endless combinations of processes, materials, and finishes.

Here are some commonly used by our customers in the Aerospace industry:

How to Calculate Your CNC Machine’s Power Consumption

What Determines the Hourly Rate for CNC Machining?

What’s the Real Price of a Small CNC Machine?

How Many Axes Does a CNC Machine Have?

Unlocking the Axes of CNC Machines: A Complete Guide

How Loud Are CNC Machines? The Truth About Workshop Noise

Fictiv Expert Guidance on Aerospace Product Development

Abhishek Das is a Fictiv Customer Program Manager with over 7 years experience in aerospace design and manufacturing and Samson Olanrewaju is a Fictiv Technical Applications Engineer with over 10 years of aerospace engineering experience.

Here are their top tips:

- Fundamental Principles:

- Understand the basics and fundamental principles behind aerospace engineering, including aerodynamics, fluid mechanics, materials science, and propulsion systems.

- Material Research and Testing:

- Focus on learning about the materials you are using. Research them and test them out.

- Understand the finishing processes and why you should choose one over the other.

- Software Proficiency

- Gain proficiency in industry-standard software like ANSYS, MATLAB, SolidWorks, etc.

- Understand how to leverage these tools to your advantage.

- Don’t overlook surface modeling as it can be a powerful tool in your engineering arsenal.

- Computational Fluid Dynamics (CFD):

- Develop a great understanding of CFD, as it can reduce design iterations.

- Design for Manufacturability:

- Consider manufacturability when designing any part.

- When setting up a model tree in CAD, keep the process flow in mind.

- Stay updated with current manufacturing technology improvements.

- Hands-on Manufacturing Experience:

- If you have access to a machine shop, try manufacturing processes yourself.

- Geometric Dimensioning and Tolerancing (GD&T):

- Learn to master geometric tolerances early on; this prevents excessive use of direct limit tolerances.

- Consider tolerance stack-up early in assembly design.

- Prototyping:

- Utilize 3D printing for prototyping CNC machined parts.

- Gain as much hands-on experience with prototyping as possible.

- Poka-Yoke Principle:

- Apply the poka-yoke principle when designing fixtures/jigs, theorizing about manufacturability, and determining how to assemble parts.

Why Aerospace Companies Choose Fictiv

10x Tighter Tolerances

Fictiv can machine parts with tolerances as tight as+/ – 0.0001 in -10x greater precision compared to other leading services.

Increased Productivity

Engineers get time back by not dealing with immature supply chains or lack of supply chain staffing in their company and get parts fast.

With quotes in minutes and parts in days, aerospace engineers can reduce cycle times by as much as 50% with Fictiv.

World Class Quality

Fictiv provides aerospace parts for leading aerospace enterprises, verified to be compliant with ISO9001 quality standard by a certified registrar. Also, our network includes AS9100 certified manufacturing partners, as needed.

Nadcap special process certified finishing shops integrated in our fortune-500 network.

Honeywell Aerospace

Using Fictiv, the manufacturing engineering team at Honeywell Aerospace was able to cut down the lead time for a critical component in the RE100 Auxiliary Power Unit (APU) from 22 weeks to just 3 weeks.

Find the Right Material

Explore popular material choices based on key characteristics like corrosion or UV resistance.