Online CNC Machining Service

Machined prototypes and production parts in as fast as 1 day. Request an online quote today.

Certifications ISO 9001:2015 | AS9100D | ITAR

Advanced CNC Machining Services

Introducing our expanded automated CNC milling services. Designed to streamline your prototyping and product development process, get high-quality parts in 5-9 days.

Get a Quote →

CNC Machining Materials

Metals

Aluminum

Aluminum is a popular choice for machining due to its low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion. Aluminum alloys, such as 6061-T651, 7075-T651, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost.

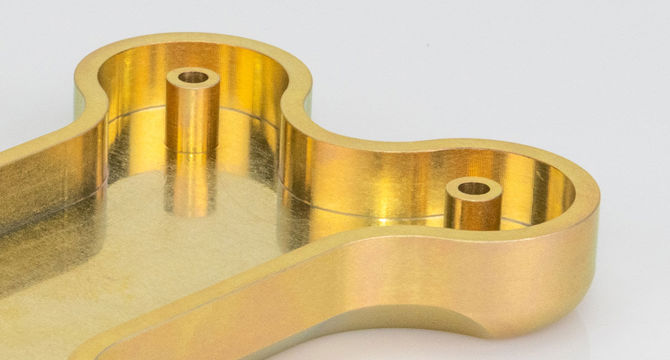

Brass

Brass is an alloying consisting of both copper and zinc. The gold materials is a weather- and corrosion- resistant metal with tensile strength similar to mild steel. It’s also an easy to machine material, so feedrates can remain high and coolant need is minimal.

Copper

Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-reddish appearance is instantly recognizable, and the metal looks attractive even when it goes through a natural oxidation process that forms a bluish-green coating called patina in response to its environment. Note, however, that copper weldability is considered moderate to poor.

Stainless Steel

Stainless steel is well-suited for a wide array of CNC machining projects, due to its excellent machinability and outstanding uniformity. It also has good workability and weldability to match your specific machining needs, as well as high ductility and formability to meet the specification requirements of any project.

Steel Alloy

Steel Mild Low Carbon

Titanium

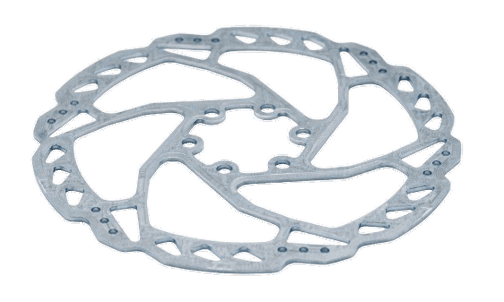

Titanium is a popular material for CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. However, titanium presents unique challenges in machining due to its high strength, low thermal conductivity, and tendency to work harden during cutting.

Plastics

Aluminum

Aluminum is a popular choice for machining due to its low density, good mechanical properties, high thermal and electrical conductivity, and resistance to corrosion. Aluminum alloys, such as 6061-T651, 7075-T651, and 2024-T351, are commonly used in CNC machining because they offer a good balance of strength, machinability, and cost.

Brass

Brass is an alloying consisting of both copper and zinc. The gold materials is a weather- and corrosion- resistant metal with tensile strength similar to mild steel. It’s also an easy to machine material, so feedrates can remain high and coolant need is minimal.

Copper

Copper is a metal that is corrosion-resistant, extremely electrically conductive, and highly ductile. Its glossy orange-reddish appearance is instantly recognizable, and the metal looks attractive even when it goes through a natural oxidation process that forms a bluish-green coating called patina in response to its environment. Note, however, that copper weldability is considered moderate to poor.

Stainless Steel

Stainless steel is well-suited for a wide array of CNC machining projects, due to its excellent machinability and outstanding uniformity. It also has good workability and weldability to match your specific machining needs, as well as high ductility and formability to meet the specification requirements of any project.

Steel Alloy

Steel Mild Low Carbon

Titanium

Titanium is a popular material for CNC machining due to its excellent strength-to-weight ratio, corrosion resistance, and biocompatibility. However, titanium presents unique challenges in machining due to its high strength, low thermal conductivity, and tendency to work harden during cutting.

Factory vs. Network

We offer a range of capabilities through our in-house digital factories at Promakehub along with our digital network of manufacturers. If speed is essential, our factory capabilities have you covered, but if you’re in need of advanced capabilities and have more flexibility in your schedule, try Promakehub Network.

Factory Capabilities for CNC Milling | Network Capabilities for CNC Milling | ||

| Maximum Part Size | 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.3mm) | 25.5 in. x 25.5 in. x 11.8 in. (650mm x 650mm x 300mm) | |

| Minimum Part Size | 0.25 in. x 0.25 in x .0.04 in.(6.35mm x 6.35mm x 1.016mm) | 0.0393 in. x 0.0393 in. x 0.0393 in.(1mm x 1mm x 1mm) | |

| Tolerances for Parts without Technical Drawing | +/- 0.005 in. (+/- 0.127mm) | ISO 2768-1-1989-f (metals), ISO 2768-1-1989-m (plastics) | |

| Tolerances for Parts with Technical Drawing | Linear tolerance quoted to ISO 2768-1-1989-f, Standard hole tolerance quoted to +/- 0.005 in. (+/- 0.127mm) Hole & bore-style tolerance on specified feature may be +/- 0.0005 in. (+/- 0.0127mm) | Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | |

| Radii | Sharp inside corners on a part will be radiused (rounded) as a natural result of the CNC machining process. | ||

| Text | Plastic and soft metals: Minimum width of 0.018 in. (0.457mm), depth of 0.0118 in. (0.3mm). Example text size would be 16 point Arial Rounded MT font. Hard metals: Minimum width of 0.033 in. (0.838mm) and depth of 0.0118 in. (0.3mm). Example text size would be 22 point Arial Rounded MT font. | ||

Surface Finish and Post-Processing Options

Promakehub offers a variety of CNC machining surface finishing options to meet your part requirements. More advanced coating and plating options are also available.

Surface Finish Options:

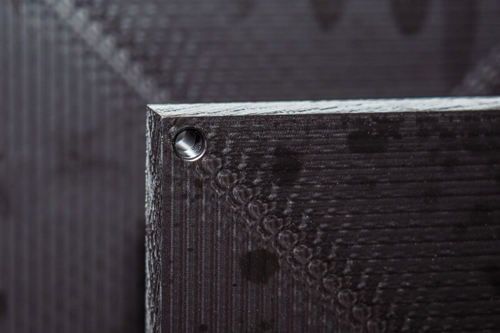

- Edges broken with tool marks visible

- Edges broken with light bead blasting

- Sharp edges (tool marks visible)

Coating and Plating Options:

- Anodizing

- Chromate coating

- Powder coating

- Zinc coating

- Nickle plating

Why Choose Us for Custom CNC Machining?

What is CNC Machining and How Does it Work?

CNC machining is an automated manufacturing process that transforms a solid block or rod of material into a part using end mills. The end mills are controlled by software (G-code) which references a 3D CAD model to reduce the stock material into a desired geometry. Parts can be manufactured relatively quickly due to the level of automation.

There are many types of CNC machines, which include CNC milling and CNC turning. CNC machining is a suitable manufacturing process for one-off prototypes or custom components as well as mid-volume production quantities.

Advantages of CNC Machining

The subtractive process of CNC machining provides multiple benefits for both prototyping and production parts.

- Precision and repeatability

- Tight tolerances

- Production-grade materials

- Quick-turn parts within 1 day

- Lower piece-part price at higher quantities

- Robust post-processing to improve cosmetics and material properties

CNC Machining Applications

CNC machining is widely used throughout the aerospace, medical, automotive industries for its ability to rapidly manufacture precise parts in production-grade materials. Typical CNC parts, include:

- Housings and enclosures

- Brackets

- Fixtures for manufacturing

- Gears and bearings

- Internal mechanical components

- Medical instrumentation

F.A.Q.

Supporting Subheading

CNC machining is a very effective solution for limited runs and lower quantity parts. Price depends on the material chosen, complexity, quantity, and required lead time. Prices for geometry manufacturable by CNC versus 3D printing are relatively comparable, but typically machining offers improved material properties and surfaces. The best way to find your exact price is to submit a 3D CAD model and get an interactive quote with design for manufacturability (DFM) feedback. The automated and semi-automated manufacturing sites are best suited for high mix, lower quantity solutions. Pricing for higher volume part quantities are best quoted through our Protolabs Network.

At all our fulfillment locations, we offer UNF, UNC, and metric threads. Our automated factory can machine parts for coil and key inserts without supplying or installing them. In our semi-automated factory and Protolabs Network, we provide the same threading options, plus SM1, SM2, and SM3 lens threads. We can also install hardware like standard coil inserts, key inserts, and heli-coils at these locations

Maximum part size will vary based on your selected material. Our largest part size offered is 22 in. x 14 in. x 3.75 in. (559mm x 356mm x 95.25mm) and is available in Aluminum 6061 and 7075

Additional Links and Resources

Explore popular material choices based on key characteristics like corrosion or UV resistance.